Laser analyzer and fast IR filter spectrometer detect emission peaks

Just imagine how dense the air in the cities would be today without the catalytic converter in the car. The regulated three-way catalytic converter, which has been obligatory for new vehicles in Germany since the end of the 1980s, ensures a drastic reduction in harmful emissions by means of exhaust aftertreatment. Moreover, ever stricter legal regulations and standards worldwide require new technologies to reduce exhaust emissions. With the aid of suitable measurement technology, the efficiency and reliability of catalytic converters can be tested and engine and exhaust gas management can be optimized. In order to achieve the required limit values, highly dynamic processes in the combustion engine must be increasingly investigated and optimized.

Measurement in the exhaust gas system at the catalytic converter or directly in the combustion chamber

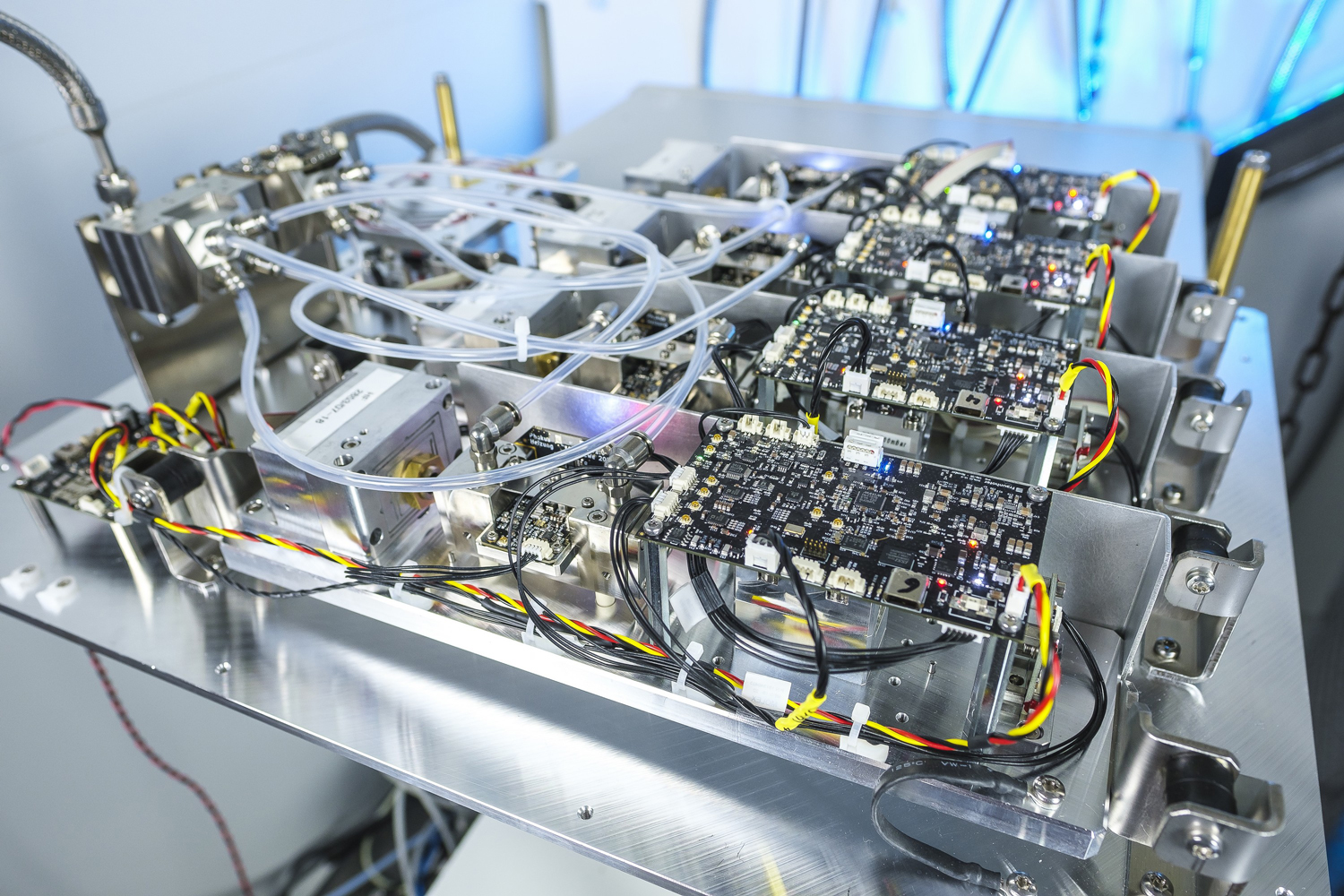

Fraunhofer IPM has developed a series of spectroscopic analysis systems for the measurement of exhaust gases. These systems simultaneously measure several gas components at different sampling positions – with high selectivity and time resolution. They detect fast emission peaks and thus provide insight into the dynamic combustion processes of a car engine. In addition to fast analyzers based on quantum cascade lasers (QCL), our portfolio also includes a fast IR filter spectrometer for the test bench which is used to measure hydrocarbons in the car exhaust system. The system measures the concentration of different exhaust gas components simultaneously with a time resolution of 5 milliseconds and thus serves to analyze and optimize dynamic processes in multi-stage catalytic converter systems.