Summer School / 2025

Fraunhofer Photonica 2025: Starting point for a research career

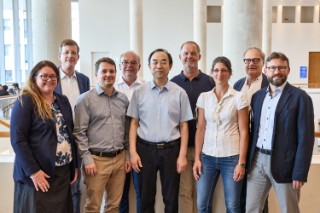

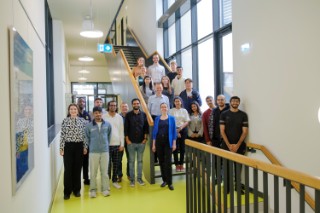

Nineteen young scientists from around the world visited three Fraunhofer institutes to gain insights into photonics research. The week-long trip, from 22 to 27 September, took them around Germany from Freiburg to Karlsruhe and Ettlingen, and then to Aachen. The Fraunhofer Photonica was organized by the Fraunhofer Light & Surfaces Group, under the direction of the Fraunhofer IPM.

more info