Quantum sensors: How does the flow profile affect flow measurements?

Researchers at Fraunhofer IPM have developed a contactless flow measurement method based on magnetic fields. For the first time, they have been able to show the quantitative impact of the flow profile on the magnetic signal. This opens up new possibilities for improving the measurement method. The results were recently published in the “Journal of Applied Physics”.

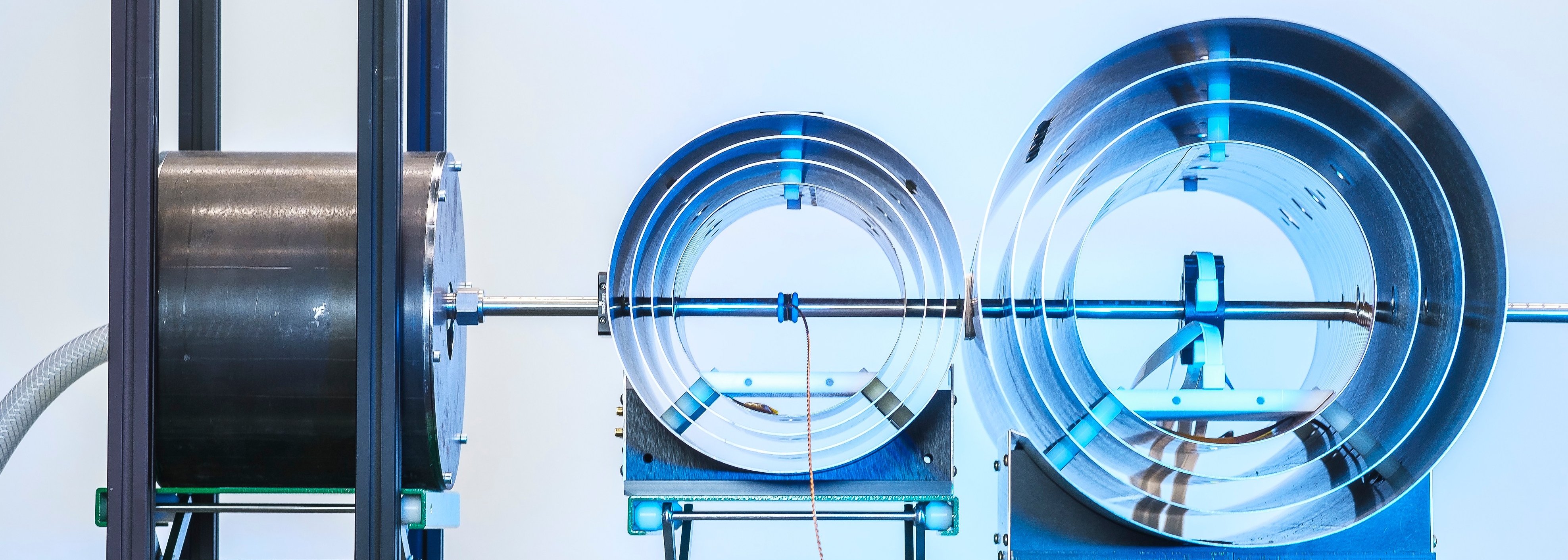

There are many manufacturing processes across various industries where flowing liquids play a key role. Controlling or automating such processes requires reliable data on the flow rate of the liquids. A magnetic field-based flow measurement technique developed at Fraunhofer IPM provides accurate flow data without any contact with the liquid. The first step is to magnetically polarize the liquid medium with a permanent magnet. In a second step, this polarity is reversed using high-frequency impulses. This creates local magnetic markers in the fluid, which are detected in a third step by highly sensitive quantum sensors through the pipe wall after the fluid has flowed through a defined section. This method can be used to determine the flow velocity of a magnetizable fluid.

Mapping the magnetization distribution

The flow profile has a strong effect on the strength of the marker in this measuring method. Researchers at Fraunhofer IPM have been able to prove this using a model of the magnetization distribution in a flowing fluid. They simulated both effective flip angle distribution and temporal development of the magnetization, and discovered that the variation of the flow velocity widens the distribution of the flip angles across the pipe diameter, attenuating the magnetic signal. With this deeper understanding, the researchers are now able to further optimize the measurement method. According to Leonhard Schmieder, researcher at Fraunhofer IPM and lead author of the publication, this research project was the first to implement the mapping approach in a zero-to-ultra-low-field magnetometry-based experiment using nuclear magnetic resonance. “Our contactless measuring approach is suitable for a wide range of applications. Our method stands out whenever non-invasive, accurate and efficient solutions are required,” says Schmieder.