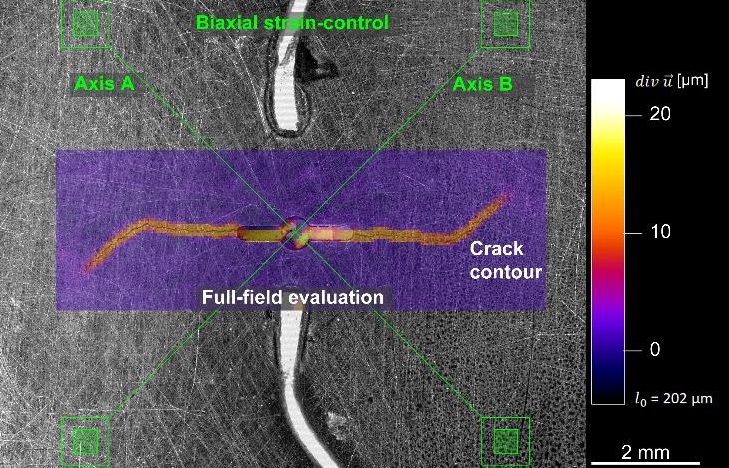

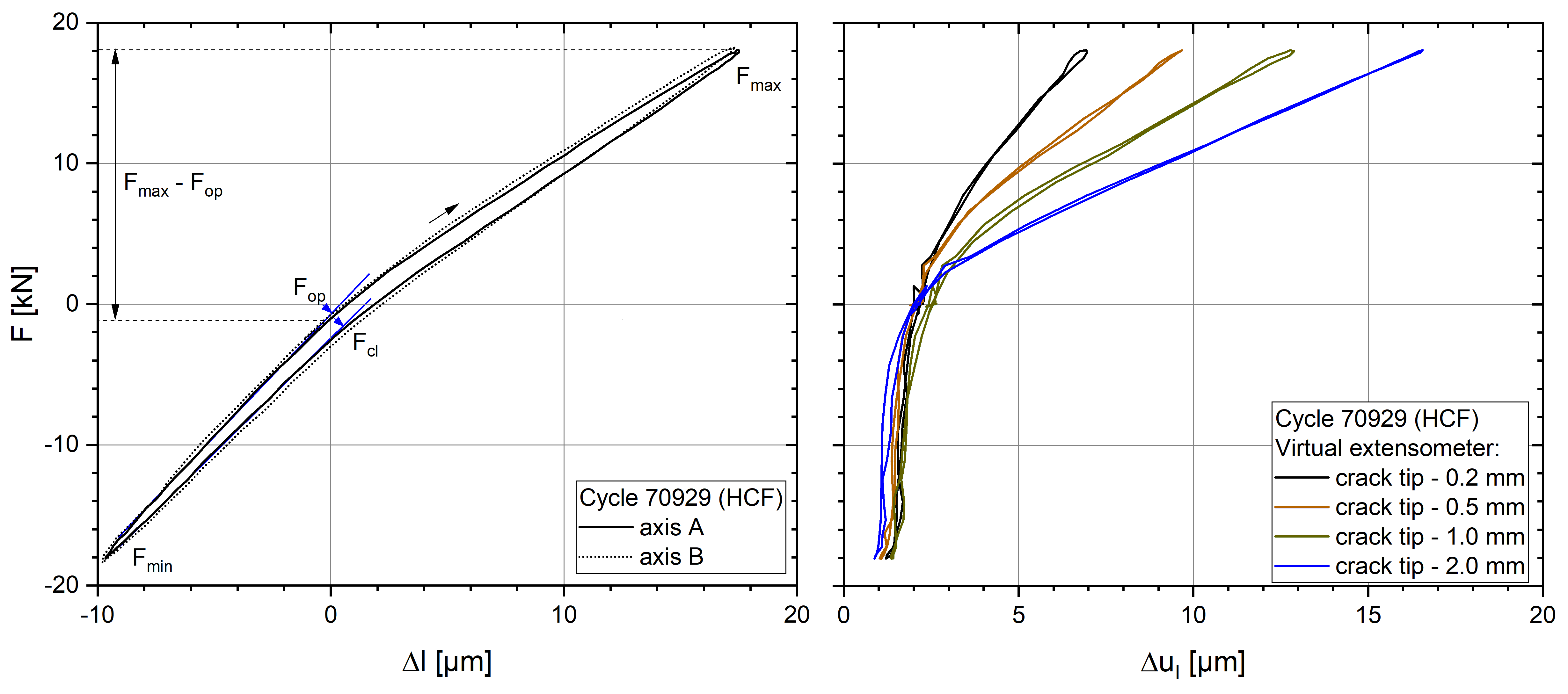

Digital image correlation (DIC) is an established image processing method used in materials research to measure strain and displacement of samples under load at subpixel level. For example, a change in length due to integral strain can be measured as the difference in displacement between two image areas, comparable with a mechanical extensometer. In crack propagation experiments, crack path, crack length and crack flank displacement can be measured within the strain field to characterize the opening and closing behavior of the cracks that are forming.

Due to the high computational load, this process can be very slow when using conventional processors, which makes it impossible to adhere to the recommendations of relevant standards such as ASTM E606 regarding strain control or ASTM E647 on the evaluation of crack propagation tests.

GPU enables strain measurement with measurement rates of up to 1500 Hz

The solution is the use of graphics processing units (GPU) that make it possible to measure integral strain – like mechanical extensometers – at a rate of up to 1500 Hz, and to process up to 200,000 correlation subsets per second in real time during full-field analysis.

Fraunhofer IPM’s »real-time optical displacement measurement system« (RODiS) is the first optical strain measurement system to enable strain-controlled fatigue tests according to ASTM E606, as well as fast, contactless and marker-free crack propagation compliance measurements pursuant to ASTM E647 for metallic samples at temperatures of up to 1000 °C. In this context, »marker-free« means that the sample does not have to be treated with a marker (such as speckle varnish); instead, the untreated microstructure can be used as correlation pattern.