Detecting slipped loads or open hatches on the train

Load slippage represents a safety risk in rail traffic, particularly in stations or tunnels where it can cause accidents with serious consequences. In order to detect any defects and acute dangers in rolling stock at an early stage, the external geometry of trains should be recorded – preferably automatically and during the journey.

Sector Profile Scanner SPS

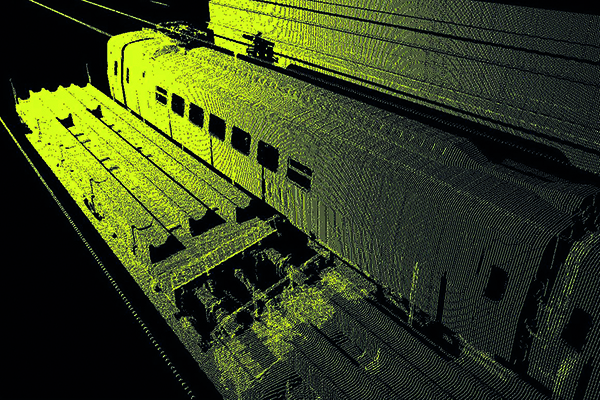

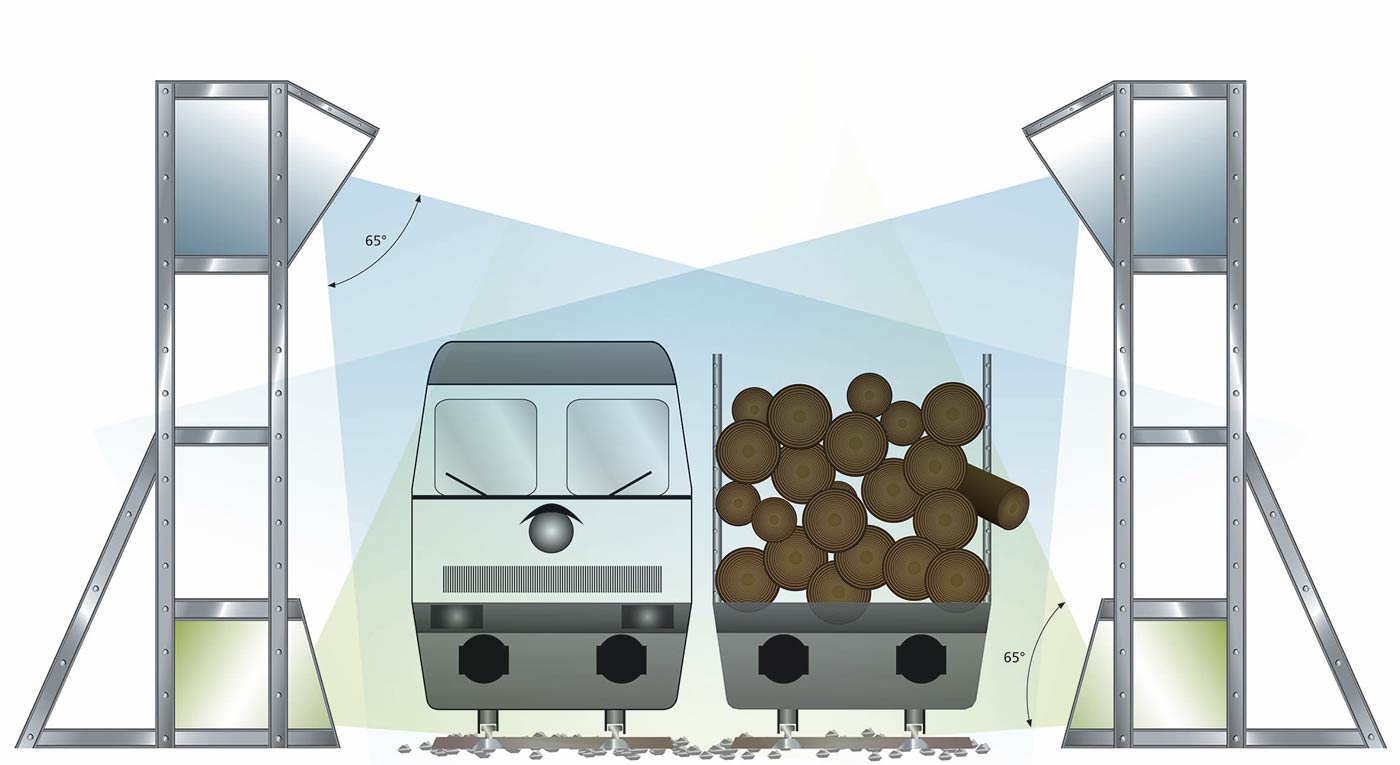

It is precisely for this purpose that Fraunhofer IPM has developed special laser scanners for a measurement portal measuring the geometric shape of passing trains. The optical sensor system SPS consists of four laser scanners installed as part of a measurement portal. Thanks to extremely high measurement rates, the train does not need to reduce its travel speed when passing through the portal. A three-dimensional image is available immediately after the train has passed through. It shows any geometric irregularities such as slipped or protruding loads, loose tarpaulins, open doors, deformed containers or detached connections between the wagons.